Conduction Cooled Stacks

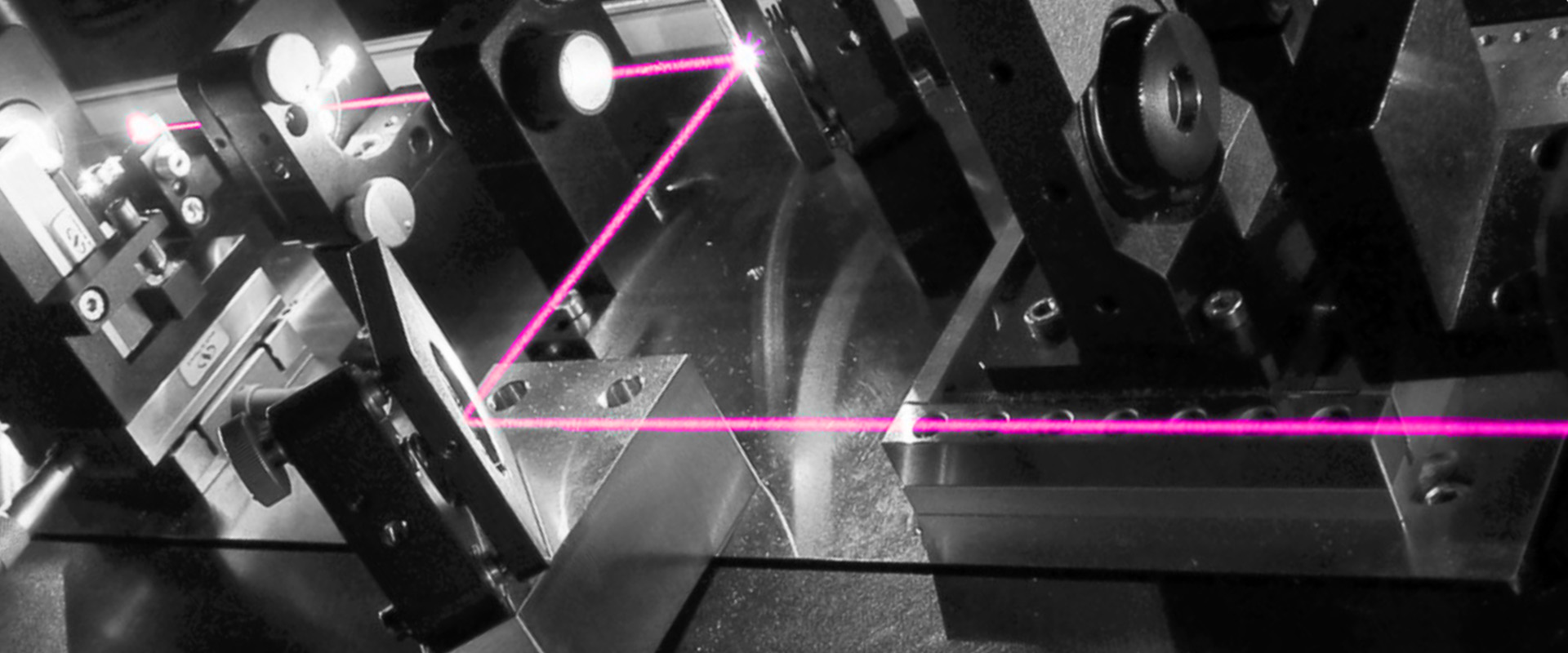

808 nm Quasi-CW Diode Laser Stacks – QCP & BCC Series

Features and Benefits:

- High power quasi-CW diode laser stacks (vertical/horizontal)

- 100 W / 200 W per bar: scalable with multiple bars up to multi-kW

- Bar-to-bar spacing 0.4 mm – 3.5 mm

- Repetition rate 1 Hz – 25 Hz

- Pulse width 20 – 400 µs

- High power conversion efficiency

EVERBRIGHT produces customized vertical and horizontal arrangements of multiple diode bars (multi-bar modules), delivering very high output power up to multi-kW power levels.

Data Sheets:

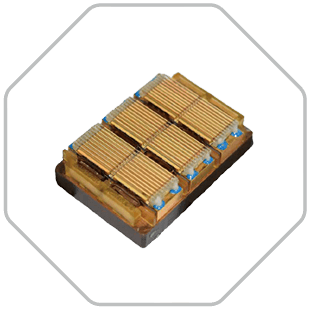

Micro Channel Cooled Stacks

808 nm Diode Laser Stacks – MCP Series

s

Features and Benefits:

- CW up to 100 W per bar

- Quasi-CW up to 300 W per bar

- Scalable with multiple bars

- > 20 Million pulses

- High power conversion efficiency

EVERBRIGHT´s MCP Series indium-free hard solder package micro-channel water-cooled arrays provide stable performance, high reliability and long lifetime. The hard solder package macro-channel array with back heat dissipation is using special water channels or conduction cooling design to reduce the requirements for water quality. This type of diode laser stacks provides an outstanding life expectancy of 20 million pulses or more.

Data Sheets:

High-Power Diode Lasers from Everbright Photonics

Everbright Photonics is specialized in high-power diode laser chips, high-efficiency diode laser radar sensor chips, high-speed communication diode lasers and related optoelectronic devices and application systems. Everbright is committed to the development and production of diode laser chips, significantly improving the performance of laser chips, leading domestic and international advanced technical indicators, and strongly promoting the process of localization of diode laser chips. With a strong engagement in R&D and complete in-house production of diode laser chips, several key breakthroughs have been made in core technologies such as chip design, MOCVD, lithography, cleavage/coating, package testing, and fiber coupling. EVERBRIGHT has developed a fully automated production line for high power semiconductor lasers. Active Alignment, covering all processes from fast axis collimated lens assembly to fiber coupling, which can quickly produce high power, multi-band laser modules.